2023.03.22 Patent

Key Points to be Noted in Order to Obtain a Decision that Acknowledges Compliance with Support Requirement in Patent Applications Filed through Model Experiments

1. Introduction

Non-compliance with Support Requirement is often found particularly in Specifications (i.e., one of application documents) of chemical inventions in relation to examples disclosed. It is therefore crucial to give consideration to descriptions of Specifications in light of Support Requirement. “Support Requirement” in Japanese Patent Act is a requirement that an invention for which a claimed patent is solicited shall be disclosed in the detailed description of the invention (Patent Act 36-6(1)). Regarding a framework for determining Support Requirement, the Intellectual Property (IP) High Court Special Division has indicated “standard for determination” in its ruling (No. 2005 (Gyo-ke) 10042, November 11, 2005) as detailed below:

“whether or not recitations in the claims comply with Support Requirement is to be judged by considering, based on comparison between the recitations in the claims and the descriptions in the detailed description of the invention, whether the invention claimed in the claims is the invention descried in the detailed description of the invention and (i) whether the invention is within a scope that allows a person skilled in the art to recognize that the problem of the invention can be solved based on the descriptions in the detailed description of the invention, or (ii) even when such descriptions or suggestions are not found, whether the invention is within a scope that allows a person skilled in the art to recognize that the problem of the invention can be solved in light of the technical common knowledge at the time of filing of the application.”

Inventions requiring large-scale facilities for actual implementation face difficulties in having a real-scale experiment required for completing the inventions due to cost and experimental difficulties. In many cases, there is no choice but to use model experiments. Patent applications including examples based on model experiments themselves should be practically permitted; however, in this case as well, an attention should be paid to whether the Specification is written in a manner to comply with “standard for determination”. Hereinafter, we would like to introduce a useful case that shows what points to be focused in the patent applications of these types from the view point of Support Requirement.

2. Introduction of Related Case: IP High Court Ruling on Case Seeking Rescission of Trial Decision (No. 2016 (Gyo-ke) 10215, October 26, 2017)

[Case Summary]

This case is a suit for seeking rescission of the Trial Decision in the patent invalidation trial of the invention pertaining to “mold powder for continuous casting of steel” (Japanese Patent No. 4725133). The IP High Court has rescinded the Trial Decision to dismiss the request for the patent invalidation trial for the reason that the subject patent does not comply with Support Requirement.

[Overview of the Subject Patent]

Claim 1 (Invention 1 of the subject patent) is shown below. Claim 2 (Invention 2 of the subject patent) is omitted.

[Claim 1] (Invention 1 of Subject Patent)

A mold powder for continuous casting of steel to be used for continuously casting low carbon-aluminum killed steel containing:

C: 0.02 to 0.05% by mass (excluding 0.05% by mass);

Si: 0.1% by mass or less;

Mn: 0.05 to 0.3% by mass;

P: 0.002 to 0.035% by mass;

S: 0.005 to 0.015% by mass; and

sol.Al: 0.02 to 0.05% by mass,

the mold powder for continuous casting including at least SiO2, CaO, and Na2O, the mold powder for continuous casting exhibiting excellent detachability from a slab surface in a secondary cooling zone, and the mold powder for continuous casting being configured to achieve improved performance of cooling a cast slab in the secondary cooling zone, characterized in that:

a relation between a SiO2 content and a Na2O content of the mold powder falls within a range satisfying the following formula (i), and

a relation between a basicity of the mold powder and the Na2O content of the mold powder falls within a range satisfying the following formula (ii) (excluding the case of […]):

0.65×[%Na2O] +25≤[%SiO2]≤2.08×[%Na2O]+25……(i)

-0.078×[%Na2O] +1.4≤CaO/SiO2≤-0.077×[%Na2O]+1.8……(ii).

wherein, in the formulas (i) and (ii), “[%Na2O]” is the Na2O content (% by mass) of the mold powder, “[%SiO2]” is the SiO2 content (% by mass) of the mold powder), “[%CaO]” is the CaO content (% by mass) of the mold powder, and “CaO/SiO2” is the basicity of the mold powder.

The following is brief descriptions of the Specification of the subject case (hereinafter, referred to as “subject Specification”) that are relevant to the ruling.

• The object of the subject patent is “to provide a mold powder for continuous casting of steel that exhibits excellent detachability from a slab surface and is configured to achieve an improved performance of cooling a cast slab in a secondary cooling zone”. The invention has an effect that “by continuously casting molten steel using the mold powder of the subject invention, the mold powder that has melted and flowed into a gap between a mold and a solidified shell […] is detached quickly from the slab surface immediately below the mold. As a result, performance of secondary cooling is improved, which increases the thickness of the solidified shell of the cast slab […] bulging-induced molten metal level fluctuation is suppressed”.

• The relation between the detachability of the mold powder from the slab surface and the chemical component composition has been studied through a model experiment, and the formulas (i), (ii) above in claim 1 were derived from the result of the model experiment. Contents of the model experiment include evaluation of the detachability in which “the mold powder, melted and kept at a temperature of 1300℃, was poured into a rectangular iron container, the rectangular container was dismantled before the melted mold powder had completely solidified, and the detachability was evaluated by calculating an area ratio of the mold powder adhering to a wall of the rectangular container”. These contents of the model experiment do not fully correspond to those of an actual continuous casting.

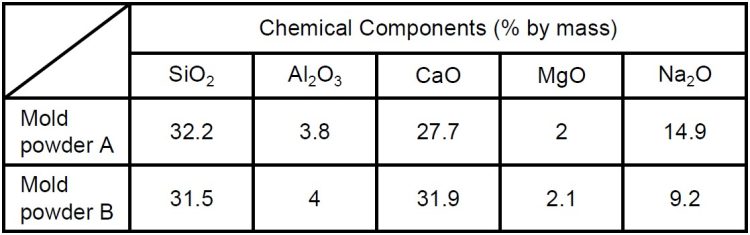

• In examples, actual continuous casting was performed using two kinds of mold powders (mold powder A neither satisfying the above formulas (i) nor (ii), and a mold powder B satisfying the above formulas (i), (ii)) having compositions shown in Table 1 below. Then, molten metal level fluctuation in each mold powder was evaluated. It was confirmed that use of the mold powder B of the subject invention can suppress the bulging-induced molten metal level fluctuation.

[Table 1]

[Judgement of IP High Court]

The judgement of the IP High Court is detailed below.

“The problem to be solved by the subject invention is to provide a mold powder for continuous casting of steel that exhibits excellent detachability from a slab surface and can achieve improved performance of cooling a mold slab in a secondary cooling zone (paragraph [0009]).

Regarding examples, the following common technical knowledge are acknowledged based on evidence (Exhibits Ko 3, 5, 7, 8, 10, 19) and the whole point of the argument.

(a) The bulging-induced molten metal level fluctuation is intensified as the thickness of the solidified shell is reduced. […] The thickness of the solidified shell is reduced (when less heat escapes into the mold and the inside of the mold is not easily cooled).

(b) The solidification temperature of the mold powder is used as an index of the cooling intensity inside the mold. […]

(c) The mold powder has a various solidification temperatures depending on its composition.

Considering the common technical knowledge above, it is acknowledged that the thickness of the solidified shell is not only determined by detachability of the mold powder from the slab surface immediately below the mold and cooling efficiency associated in the secondary cooling zone, but is also affected by the solidification temperature, which varies depending on the composition of the mold powder. […] In examples of the subject Specification, as for the mold powders A, B […], there is no description of solidification temperatures of the mold powders A, B. Table 1, which shows the compositions of the mold powders A, B, lists only chemical components of SiO2, Al2O30, CaO, MgO, and Na2O. The total amount of these components is 80.6% in the mold powder A and 78.7% in the mold powder B, which makes it unclear what the remaining components are. Thus, the solidification temperatures of the mold powders A, B cannot be estimated based on their compositions.

In addition, in the examples disclosed in the subject Specification, measurement of the bulging-induced molten metal level fluctuation during continuous casting for a mold powder satisfying neither the above formulas (i) nor (ii) and a mold powder satisfying the formulas (i), (ii) was performed merely on the mold powders A and B, respectively.

Based on these, even though the detailed description of the invention in the subject Specification suggests that mold powder B could suppress the bulging-induced molten metal level fluctuation relative to the mold powder A, it must be said that it is unclear, from the detailed description of the invention in the subject Specification, whether the reason that the mold powder B could suppress the bulging-induced molten metal level fluctuation as compared to the mold powder A was due to composition of the mold powder B satisfying the formulas (i), (ii).

[…] In the subject Specification, detailed conditions of the model experiment are unclear in many respects such as the size and thickness of the rectangular container, the amount and speed of the mold powder to be poured into the rectangular container, a time to dismantle the rectangular container, and all the details of compositions of iron and the mold powder. […] Thus, it can be said that the model experiment itself lacks reproducibility.

[…] In the model experiment, the direction of heat transfer is opposite to the direction of heat transfer in the actual continuous casting. […] Thus, the model experiment cannot be acknowledged as an experiment that gives a result reflecting a detachment state of the mold powder during actual continuous casting.

[…] Accordingly, it can be said that a person skilled in the art cannot understand that the mold powder of the subject invention satisfying the formulas (i), (ii) can solve the problem to be solved by the invention based on the detailed description of the invention in the subject Specification or common technical knowledge at the time of filing of the subject patent application.”

3. Conclusion

In the reasons for judging the subject patent as not complying with Support Requirement, the IP High Court indicates multiple issues with respect to the description of the examples and the model experiment in the subject Specification. Specifically, the indication with respect to the examples is that it is unclear whether satisfaction of the parameters recited in claim 1 of the subject application can result in solving the problem to be solved by the subject invention for the following reasons:

(i) The “solidification temperature of the mold powder”, which is not disclosed in the subject invention, may also affect the effect of the subject invention.

(ii) As the composition of the mold powder is not sufficiently disclosed, the solidification temperature cannot be estimated based on the composition.

(iii) The subject Specification includes only two examples: the mold powder B that satisfies the parameters recited in claim 1 of the subject application and the mold powder A that does not satisfy the parameters.

With respect to the model experiment, the IP High Court indicates that the subject Specification omits many conditions necessary for performing the model experiment and thus lacks reproducibility. In light of “standard for determination” above, even if some of experimental conditions are omitted, an invention would be considered to comply with Support Requirement if its specification includes an explanation that a person skilled in the art can reproduce an experiment by appropriately selecting omitted conditions based on common technical knowledge at the time of filing of an application (alternatively, if information omitted from disclosure in the specification is limited to information on easily available common technical knowledge at the time of filing of the application, and other information necessary to ensure reproducibility of the invention is properly disclosed in the specification). Thus, when omitting some of experimental conditions, it would be advisable to include the aforementioned explanation in the specification unless it is clear that such omission will not adversely affect reproducibility.

Furthermore, the IP High Court indicates that the model experiment lacks reasonability as an experiment for evaluating detachability of the mold powder because it is not regarded as an experiment that can give a result reflecting a detachment state of the mold powder during the actual continuous casting. When model experiment is used for evaluation, it is preferred to include a description that shows correspondence between the result of the model experiment and the result of the real-scale experiment (for example, an explanation that the model experiment and the real-scale experiment share a mechanism to solve the problem to be solved by the invention).

The conditions for determining that model experiment and other tests comply with Support Requirement are mentioned, with reference to the subject case, in “Trial and Appeal Practitioner Study Group Report 2021” organized by the Trial and Appeal Department of the JPO, which is briefly summarized as follows:

(a) the detailed description of the invention must include the conditions to such an extent that the model experiment is reproducible, and on the premise of this,

(b) a problem-solving mechanism, considered to be common to the model experiment and the real-scale experiment, must be clarified to the extent identifiable by a person skilled in the art; or

(c) there is a need for common technical knowledge and/or an example that shows how well the model experiment corresponds to the result of the real-scale experiment.

In order to avoid non-compliance with Support Requirement, it would be crucial to strategically determine the contents of disclosure in light of the points mentioned above so as to write a Specification in conformity with the aforementioned “standard for determination”.

Edited by Keisaku Ishihara, Natsuko Tsuji